News Story

Celebrating Five Years of Innovation at CEEE’s Daikin Lab

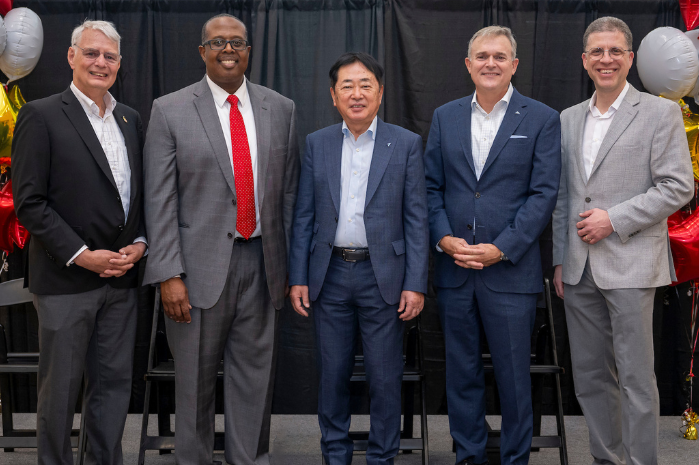

CEEE Director Reinhard Radermacher, Clark Engineering School Dean Samuel Graham, Jr., Daikin U.S. Corporation President Yoshiyuki Uemura, Daikin U.S. public policy advocate David Calabrese and UMD Department of Mechanical Engineering Chair Harry Dankowicz celebrate the fifth anniversary of CEEE's Daikin Lab.

Roving robots that blast cool air where needed, 3D-printed efficient heat-exchanger designs, a cooling system prototype that relies on metals rather than traditional refrigerants. Those are just a few of the lean and green technologies to come out of the University of Maryland’s Daikin Energy Innovation Laboratory, which celebrated its fifth anniversary earlier this month with an energy and climate innovation summit that brought together university researchers with leaders from corporate sponsor Daikin U.S. Corporation.

The anniversary commemorated the Fall 2019 opening of the Daikin Lab, made possible partly thanks to support from Daikin, a global manufacturer of heating, ventilation, air conditioning and refrigeration (HVAC&R) technologies. The 3,600 square-foot state-of-the-art facility, operated by the university’s Center for Environmental Energy Engineering, focuses on developing eco-friendly innovations in HVAC&R. The lab features climate chambers to support testing of heat pumps with lower-GWP refrigerants, heat transfer measurement facilities and test setups for experimental evaluation of alternative cooling technologies. The name recognizes the long-standing generous support of Daikin to energy engineering research and education at the University of Maryland.

“Today we celebrate the incredible collaboration between the University of Maryland and Daikin,” said Dean Samuel Graham, Jr., in his summit opening remarks. “Collaborative efforts like the Daikin Energy Innovation Lab enable us to work toward cleaner energy, smarter systems and a more sustainable future.”

Daikin U.S. Corporation President Yoshiyuki Uemura stressed that both Daikin and the University of Maryland are dedicated to innovating environmentally sustainable HVAC&R technologies – and they can achieve their aligned goals through partnership. “The Daikin Energy Innovation Laboratory has been crucial to Daikin’s efforts to research the latest in green energy HVAC technologies and to share this knowledge with the next generation of Maryland's mechanical engineering students,” Uemura said.

Climate change solutions

With the world facing a burgeoning demand for air conditioning – 1.6 billion units were in use in 2018, and 5.6 billion air conditioners are projected to be in use by 2050, according to the International Energy Agency – and an urgent need for innovations that slow climate change, researchers at UMD’s Daikin Lab have their work cut out for them.

Today’s research is just the latest in the 33-year history of the university’s Center for Environmental Energy Engineering (CEEE), which gets support from over 40 industry partners, including Daikin, and government agencies, like the Department of Energy. The center focuses on innovating the next generation of electric heat pumps, expected to play a growing role in decarbonizing heating and cooling technology.

“We don't appreciate how much heat pumps enable the lifestyle we have,” Radermacher told summit attendees. Heat pumps not only maintain the safety of a refrigerated food supply and ensure thermal comfort in buildings and automobiles, but they also keep the Internet humming along. “Data centers only work because of extensive cooling efforts – 30% of the energy consumption of data centers goes to cooling,” Radermacher said.

At the Daikin Lab, CEEE researchers are tackling big questions in an effort to innovate heat pumps that are smaller, smarter, more energy efficient and climate-friendly. Just a few of the pressing questions: Can heat pump compressors be built without moving parts by using membrane technology? Can artificial intelligence improve efficiency? How can heat pumps be optimized for cold climates?

"There’s a rhythm at Maryland. It is a rhythm that drives us to pair research that reaches beyond that which is known with a deep commitment to do good."

Department of Mechanical Engineering Chair Harry Dankowicz

The center’s strengths include its expertise in modeling and optimization, Radermacher noted, which has resulted in a suite of software used for designing heat pumps. This proprietary software gives CEEE a unique boost among universities in developing HVAC&R components. Add in insights from CEEE’s industry sponsors and collaborations with well-established international partners, and you’ve got CEEE’s winning formula for innovating the next generation of HVAC&R technologies. In the process, CEEE is feeding a steady stream of Ph.D. engineers into the workforce, ready to take on industry’s HVAC&R challenges.

Centers for excellence

CEEE is one of five centers for excellence housed in the University of Maryland’s Department of Mechanical Engineering. The summit showcased how all five centers contribute to society. “There’s a rhythm at Maryland,” said Mechanical Engineering Chair Harry Dankowicz, speaking poetically to inspirational background music as he introduced a panel session about the centers. “It is a rhythm that drives us to pair research that reaches beyond that which is known with a deep commitment to do good. To do what is good for the prosperity and well-being of the communities we serve.”

The other four centers represented were the Center for Advanced Life Cycle Engineering, the recently founded Industrial AI Center, the Center for Sustainability in the Built Environment and the Center for Risk and Reliability.

“Uniquely, in the Department of Mechanical Engineering at Maryland, we tackle challenges and opportunities at the core and at the interfaces,” said Dankowicz. “We are inventing new ways of assessing real-time performance of industrial plants and identifying bottlenecks. We are demonstrating that risk and reliability can be accounted for at the system design stage. We are investing in breakthroughs at the intersections of human health, smart homes and building design.”

Another panel session featured industry perspectives on the future of energy and climate innovation. Panelists included Kelly Hearnsberger, vice president of Daikin Comfort Technologies, North America; Deanna Archuleta, head of the The Vogel Group consulting company; and venture capitalist Tom Schull.

A future of energy innovations

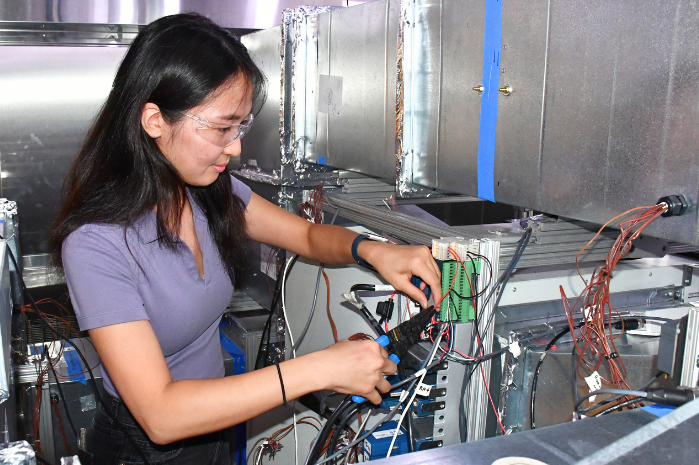

Daikin representatives enjoyed a behind-the-scenes tour of CEEE's Daikin Energy Innovation Laboratory.

Daikin representatives enjoyed a behind-the-scenes tour of CEEE's Daikin Energy Innovation Laboratory.Finally, the moment everyone had been waiting for. After a busy afternoon of presentations, Daikin execs got a behind-the-scenes tour of the lab. President Uemura, along with the other Daikin reps, stepped into the chamber where CEEE researchers are developing a wood-drying heat pump that could green the construction sector, looked up close at a prototype of the first heat pump compressor for transcritical carbon dioxide cooling that uses a liquid piston, and held in their hands 3D-printed heat exchanger designs that offer the promise of smaller, lighter HVAC&R technology.

Plans are in the works to dramatically expand the research capabilities of the Daikin Energy Innovation Lab with the upgrade of a pair of environmental testing chambers that will facilitate testing of a range of refrigerants and up to 5-ton equipment in extreme temperature environments (-25° C – 45° C). Safety upgrades will allow researchers to explore the use of refrigerants that are environmentally friendly, but pose other challenges, including flammability. “We are grateful to Daikin for their support, and look forward to continued partnership with Daikin and our other industry sponsors in our quest to innovate solutions,” Radermacher said.

As Daikin’s Uemura said in his remarks, “Together, I know that we can solve the world's most difficult and complex challenges.”

Published November 25, 2024