News Story

Director Editorial: Is there a 'new frontier' for compression technology?

Reinhard Radermacher

by CEEE Director Reinhard Radermacher, Ph.D.

Over recent years, the hermetic positive displacement compressors made considerable strides towards ever better energy efficiencies. Motor efficiencies can be in the 90% range and the isentropic efficiency of the compressor itself, depending on size, can be well over 70%. The technology is entering the region of diminishing returns. Further improvements result from changes to the cycle, such as vapor injection, staging and intercooling.

However, there is another approach. While we are used to the concept of high isentropic compression being the final frontier to strive for, it is easy to overlook that thermodynamics offers another opportunity: isothermal compression. Performance estimates for isothermal compression of carbon dioxide as refrigerant indicate an improvement of about 40% as compared to isentropic compression. This results from the fact that during the compression process the refrigerant is being cooled so that its temperature remains low.

For conventional (condensing) refrigerants, this means that the heat generated from the compression work is removed during the compression process. For carbon dioxide the challenge is greater: because of the transcritical nature of the process, the entire amount of heat rejected from the gas cooler, the sum of evaporator heat and the heat generated by the compression process is rejected during the compression process. A new concept to get used to.

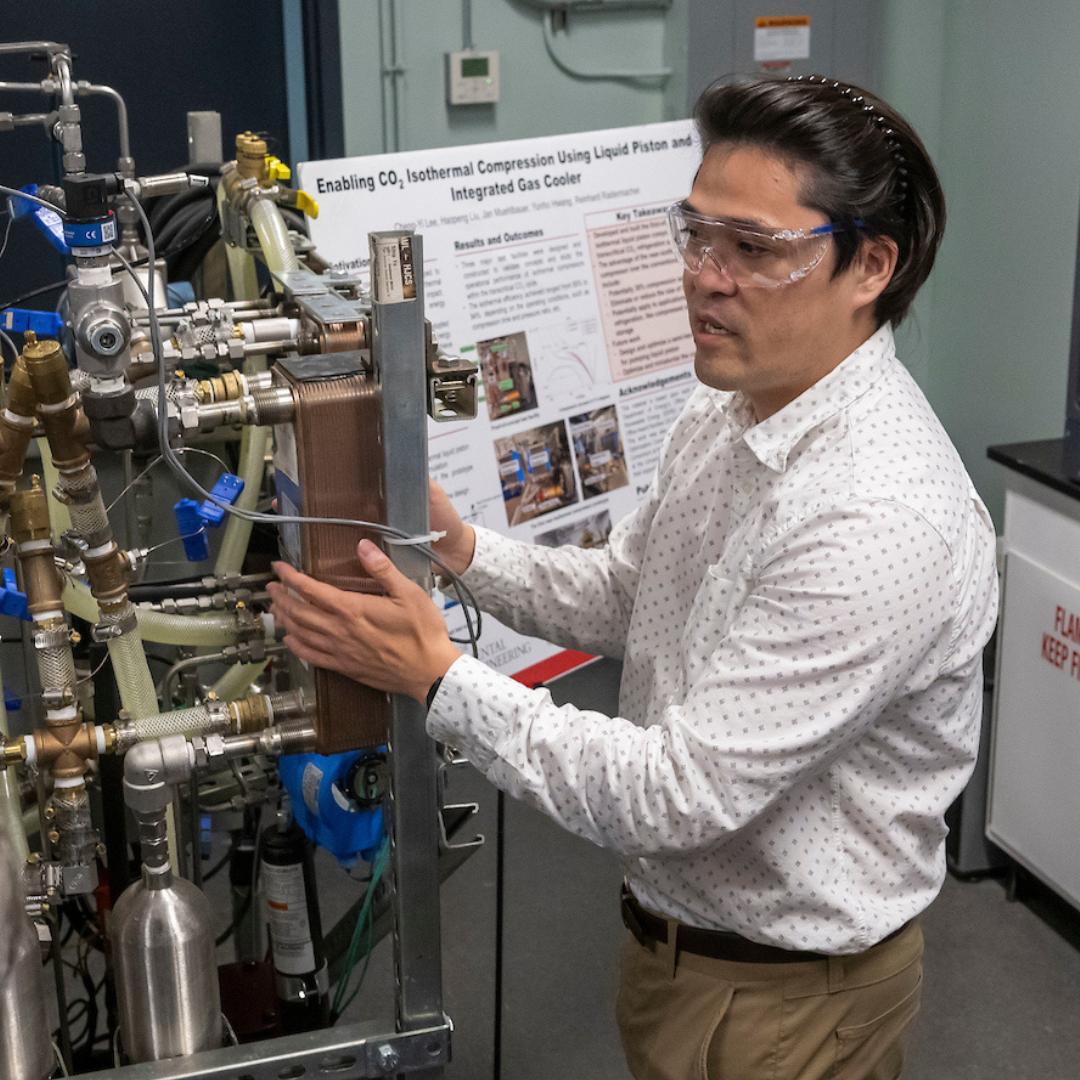

If we can address this challenge, we potentially have a very efficient refrigerant with very little climate impact compared to traditional technology. All we have to address is the challenge of how to remove the heat during the compression process. Conventional approaches aim at integrating a relatively large heat exchanger within the compressor cylinder. But how about integrating the compression process within a heat exchanger?

Published February 15, 2021