News Story

Study Investigates How to Optimize PCM-Integrated HVAC Systems

The experiment examined how phase change materials can be used more effectively to improve the performance and reliability of heating and cooling systems.

As global energy demands rise, the UMD Center for Environmental Energy Engineering (CEEE) and its collaborators are working to develop smarter ways to heat and cool buildings. A new study by CEEE and Oak Ridge National Laboratory investigates how phase change materials (PCMs) — substances that absorb and release heat as they change physical state — can be used more effectively to improve the performance and reliability of heating and cooling systems.

PCM-integrated thermal energy storage (TES) systems offer a promising approach to improving HVAC efficiency, because they store energy during low-demand times and draw on it during peak times. However, key questions remain about how to optimize PCM-based TES; the CEEE-Oak Ridge study addresses one of the core research gaps.

The study, published in Applied Thermal Engineering, offers guidance on how to best manage refrigerant subcooling in PCM-based systems. In heat pumps and air conditioners, performance depends partly on how much the refrigerant is cooled below its condensation temperature in the condenser — a process called subcooling.

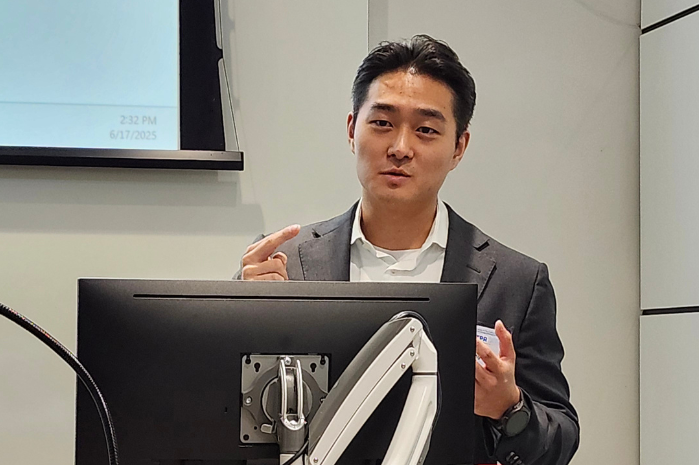

“While many studies have explored subcooling optimization in conventional vapor compression cycle systems, little research has been done on subcooling in PCM-based systems,” says co-author Research Professor Yunho Hwang, director of CEEE’s Consortium for Energy Efficiency and Heat Pumps, in the Department of Mechanical Engineering. Other co-authors are CEEE alum Yiyuan Qiao, Ph.D. ’20, and Yifeng Hu, both on the R&D staff at Oak Ridge National Laboratory.

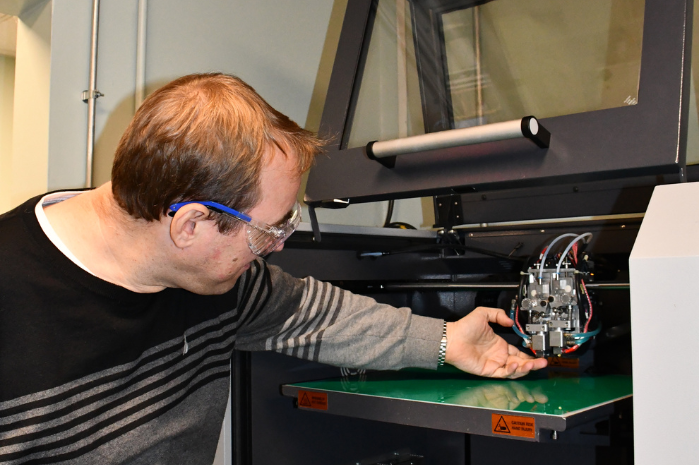

The researchers developed a parameter called nominal subcooling degree (NSD) to evaluate subcooling effects in a PCM-integrated condenser, enabling consistent comparison of condenser behavior across different operating conditions. They studied the effects of different NSDs on PCM-based heat pump performance in a controlled environmental chamber at CEEE’s Daikin Energy Innovation Laboratory.

The results indicate that there is no single “best” subcooling level for all situations. Instead, NSD selection should be application-specific. A moderate NSD of approximately 5 K is preferable for short-duration operation near the PCM melting range, while a smaller NSD of approximately 0.8 K is more suitable for extended operation requiring sustained performance. The study also provides the first systematic experimental evidence linking refrigerant subcooling to dynamic PCM melting behavior.

“These findings offer a valuable framework for improving PCM-based thermal energy storage, which could help improve the overall efficiency and reliability of HVAC systems,” Hwang says.

Download the paper: “Optimal operation of phase change material integrated condenser under various subcooling conditions.”

Published February 2, 2026