News Story

We printed a 3D heat exchanger and it works great!

3D Printed Heat Exchanger

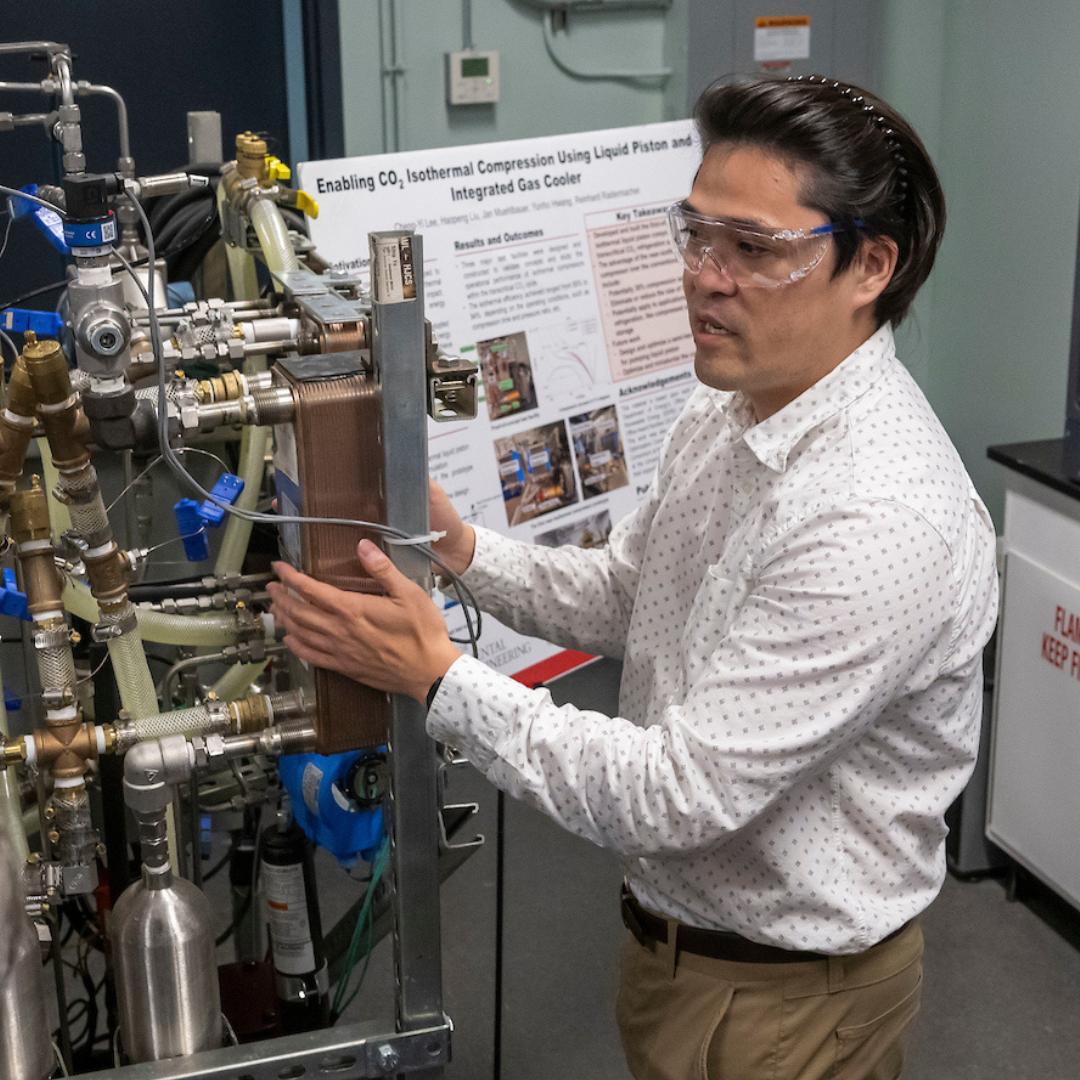

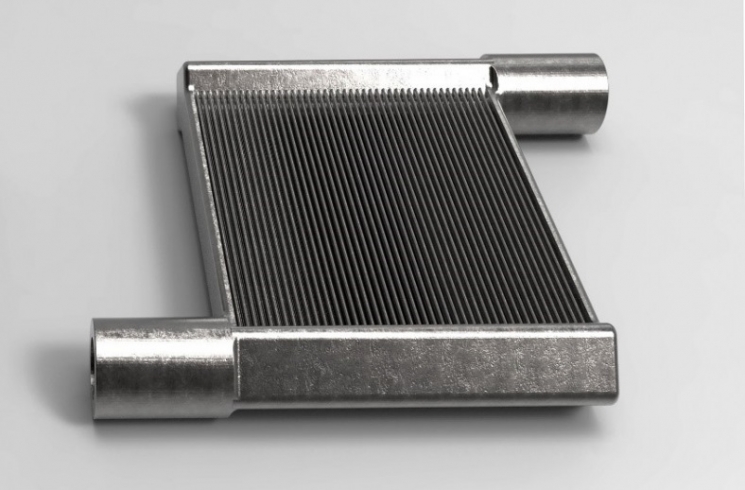

A team of Center for Environmental Energy Engineering (CEEE) students and faculty, in partnership with 3D Systems and the US Department of Energy's Building Technologies Office, used direct metal printing (DMP) to manufacture the miniaturized heat exchanger as a single, continuous piece using titanium.

It weighs 20% less and takes far less time to make than traditionally manufactured heat exchangers. And, by being printed in a continuous piece, the prototypes tend not to develop leaks and are more reliable. It also reduces waste in the process. "The prototypes take much less time to build, enabling us to do test designs much earlier and more often during research." says CEEE research scientist, Dr. Vikrant Aute.

Read more!

Cooling Post: "3D-printed heat exchanger 20% more efficient"

3D Systems: "Direct metal printing (DMP) enables CEEE to manufacture lean and green heat exchanger"

The News: "3D Printing Enables New Generation of Heat Exchangers"

The prototypes take much less time to build, enabling us to do test designs much earlier and more often during research.

Dr. Vikrant Aute

Published May 31, 2016