News Story

UMD Team Develops One of the Most Compact Heat Exchangers for Extreme Environments

A research team led by the University of Maryland Center for Environmental Energy Engineering (CEEE) recently broke new ground in the development of compact heat exchangers for high temperature/high pressure environments – such as aerospace applications, power generation systems and waste recovery – by innovating the most compact prototype reported to date, as verified through experimental testing and supported by their survey of the published literature. The researchers, who are with CEEE’s Smart and Small Thermal Systems Laboratory, presented their prototype and experimental performance results in two recent issues of International Communications in Heat and Mass Transfer.

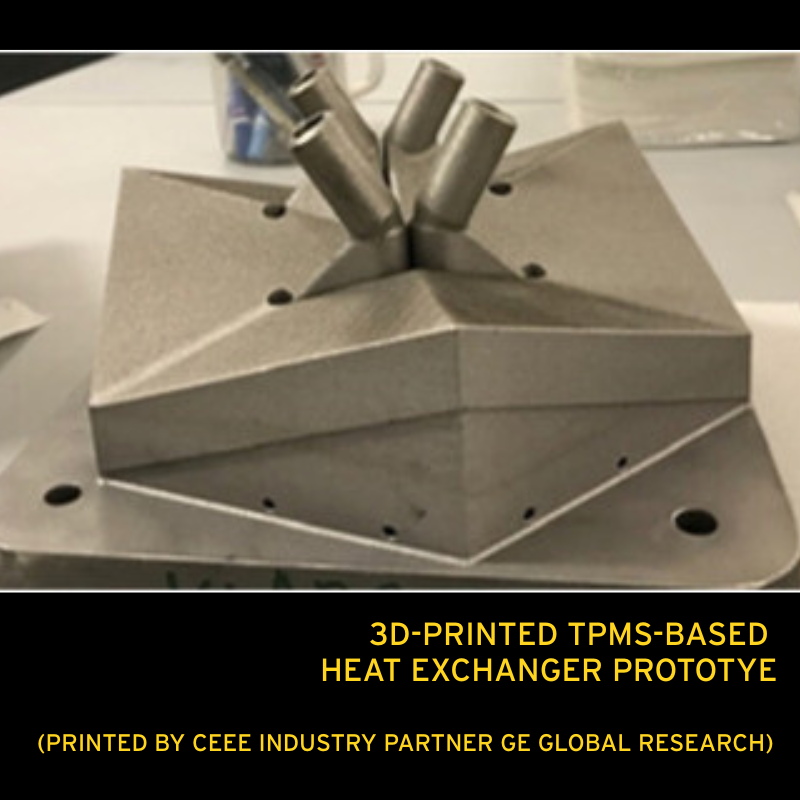

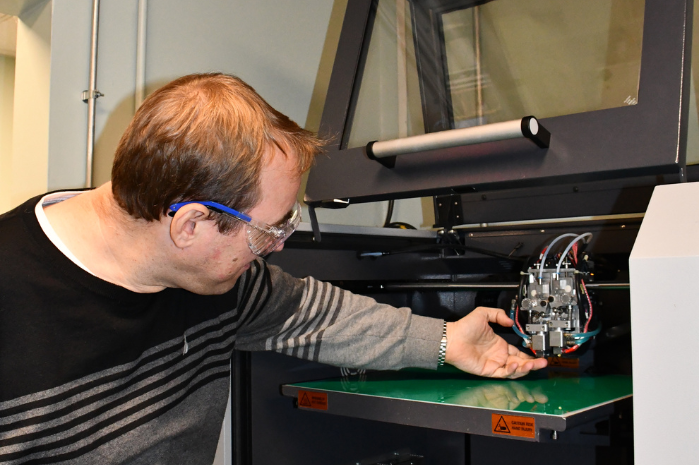

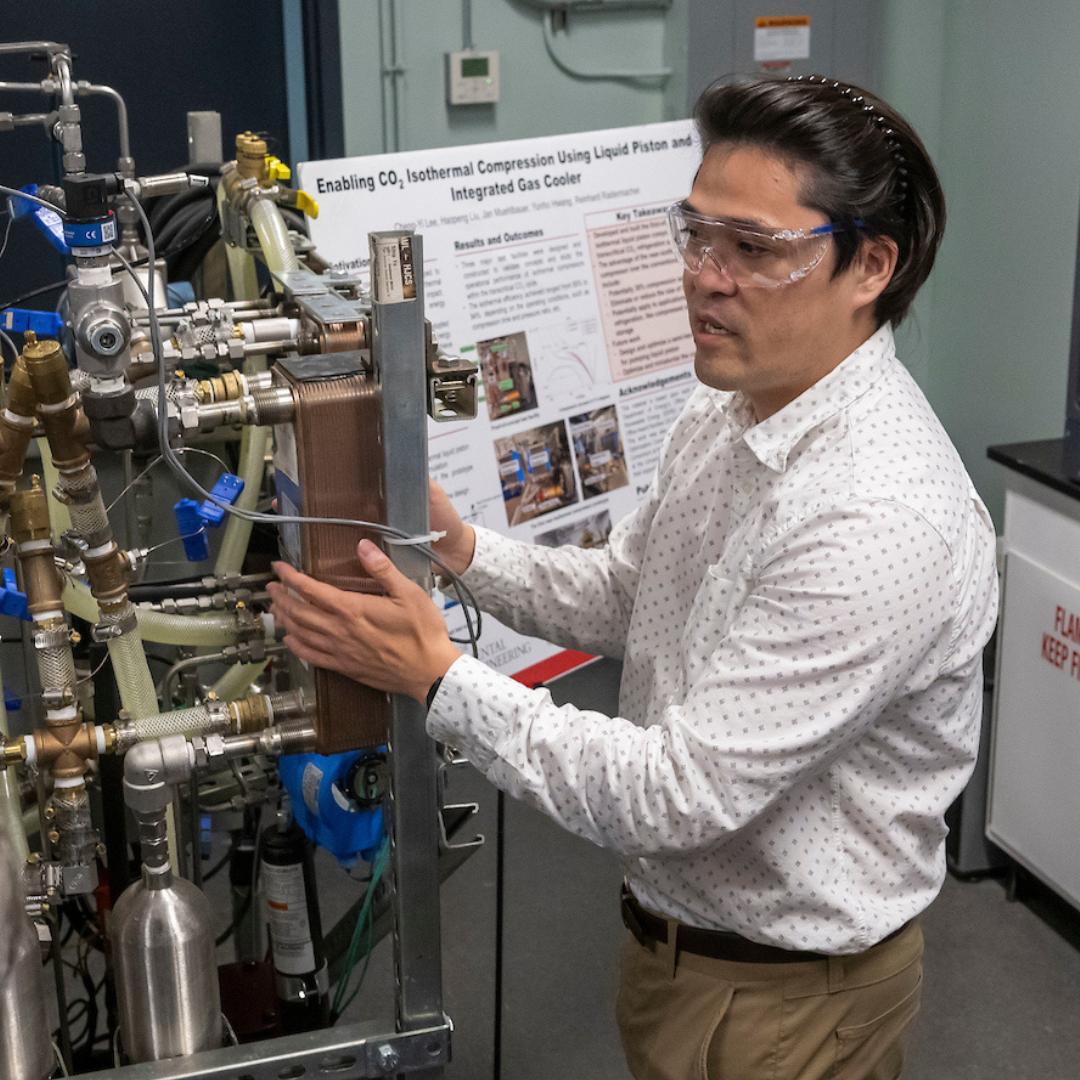

The CEEE team leveraged an additive manufacturing (3D printing) technique known as selective laser melting to fuse together layer after layer of a metal powder, fabricating a multi-pass microchannel heat exchanger (MPMHX) that can withstand temperatures and pressures higher than 800 degrees Celsius and 80 bar, respectively. The heat exchanger uses supercritical carbon dioxide (sCO2) as its working fluid, which exhibits properties of both gas and liquid phases, making it more energy dense than conventional gases and allowing for effective transport processes.

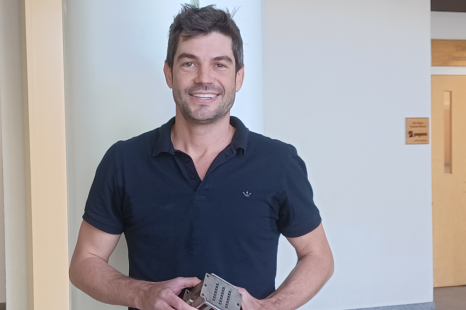

Zhengda Yao, Ph.D. ’25, is the lead author for both publications; he conducted this research as part of his doctoral dissertation and is now an R&D engineer/scientist with technology company Honeywell. Other authors are mechanical engineering Research Professor Amir Shooshtari, mechanical engineering Professor Hugh A. Bruck and CEEE Co-Founder and Minta Martin Professor of Engineering Michael Ohadi.

“This work pushes the boundaries of sCO2 heat exchanger design and performance through advanced additive manufacturing,” says co-author Shooshtari. “A key advantage of this design is its compactness, an important feature across many industries, since it reduces space requirements and maximizes efficiency, essentially enabling greater performance within a smaller footprint.”

The team’s MPMX prototype has a surface area density of 989 m²/m³ – well over the 700 m²/m³ threshold that is commonly used to define compact heat exchangers. The MPMX experimentally achieved a power density of 45.4 MW/m³, with a low pumping power requirement of 11.75 W, giving it the highest compactness reported to date, according to the team’s literature study. The researchers presented their design and fabrication process in the May 2025 issue of International Communications in Heat and Mass Transfer and shared their experimental performance results in the November 2025 issue.

Download the papers (both are open-access publications):

Design, fabrication, and hydrodynamic characterization of an additively-manufactured high power density multi-pass microchannel heat exchanger for extreme environment applications (International Communications in Heat and Mass Transfer, May 2025)

Modeling and validation of an additively-manufactured multi-pass microchannel heat exchanger for high power density applications (International Communications in Heat and Mass Transfer, November 2025)

Published September 15, 2025