News Story

UMD receives two new DOE Building Technologies awards

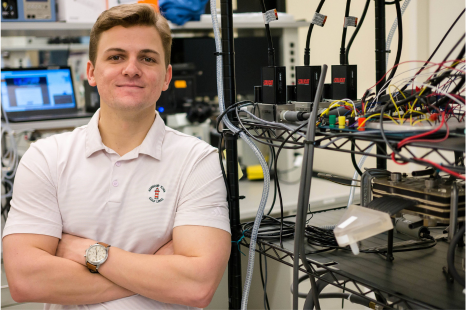

University of Maryland engineers, Ichiro Takeuchi, Professor of Materials Science and Engineering (MSE) and Graduate Program Director, Reinhard Radermacher, Director of the Center for Environmental Energy Engineering (CEEE), and Vikrant Aute, Co-Director of CEEE, recently received awards from the U.S. Department of Energy’s (DOE) Office of Energy Efficiency and Renewable Energy (EERE) Building Technologies Office (BTO).

BTO research is focused on reducing energy intensity with the most opportunity for energy savings, while balancing the need to maintain occupant comfort and productivity, and product performance. This includes both new and existing buildings, both residential and commercial, including their energy-consuming and labor-saving equipment. In the latest round of funding, BTO awarded $47.7 million to 23 projects, two of which come from UMD.

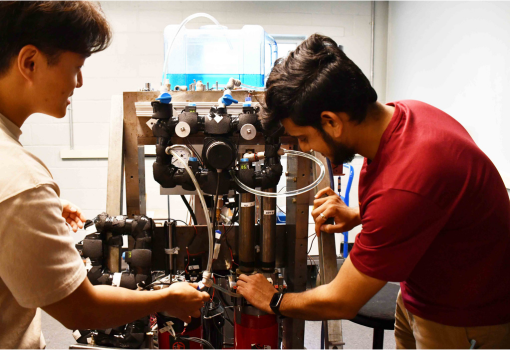

Under the topic of Flexible Building Technologies, Aute’s project: A Novel Framework for Performance Evaluation and Design Optimization of PCM Embedded Heat Exchangers for the Built Environment will create a solid-state energy storage composite phase change material and heat exchanger.

The team at CEEE, in collaboration with Heat Transfer Technologies LLC (HTT), will develop and validate a novel framework for performance evaluation and design optimization of phase change material (PCM) embedded heat exchangers (HX). These heat exchangers, when integrated with building HVAC&R equipment and envelope, provide thermal storage capabilities leading to reduction in peak energy demand. One of the deliverables of this research is an online PCM-HX design tool to assist researchers/engineers/designers in evaluating commonly used PCM-HX geometries. The framework will allow design of novel PCM-embedded heat exchangers and integrate their performance with other system/building energy simulation tools to evaluate building level impact on the demand, energy, and cost savings. The novel designs will be fabricated by HTT and then tested at CEEE labs.

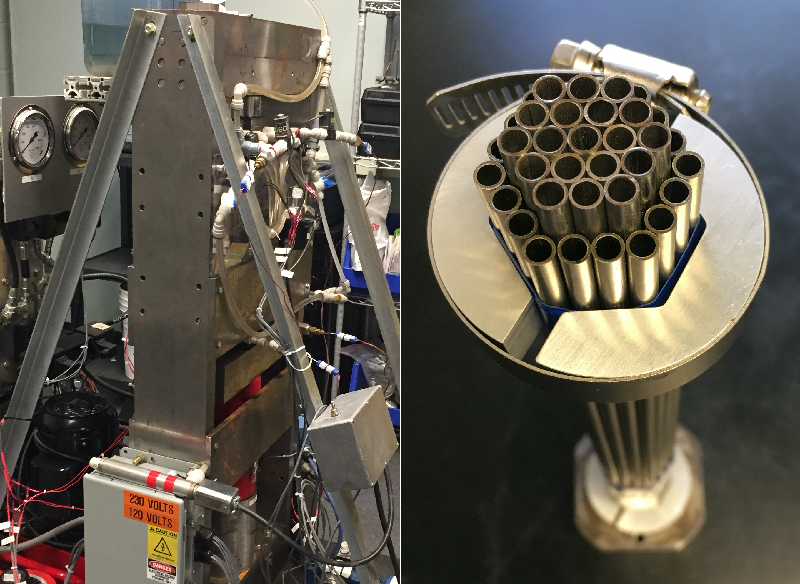

Under BTO’s second topic Heating, Ventilation and Air Conditioning, Takeuchi and Radermacher’s project will develop thermoelastic active regenerators to advance the state of the art of thermoelastic cooling technology, a potentially more sustainable and efficient alternative to vapor compression cooling technology.

The goal of the proposed project is to demonstrate for the first time thermoelastic active regenerators with hitherto unattainable system ∆T using cascade active regeneration schemes implemented to increase temperature gradient across thermoelastic refrigerants. Building on their original ARPA-E project, this project is based on an invention at UMD. It integrates fatigue-free compression-based mechanism with heat exchanger/recovery subsystems for a 400 W (by design) prototype.

Professor Takeuchi notes, “There is now a clear pathway toward substantially boosting the capacity and ∆T of thermoelastic cooling systems using active regeneration. Unlike other classes of caloric materials, thermoelastic materials have intrinsically high adiabatic ∆T (> 20 K) and operation temperature ranges exceeding 100 K. In analogy to magnetocaloric cooling, which exploits active regeneration to go from the limited adiabatic ∆T of 3-5 K to a system ∆T of 20 K, we expect the thermoelastic counterpart to be able to achieve system ∆T of 100 K by properly implementing cascade active regeneration schemes.”

The team will also develop a compact regenerator prototype using Cu-based thermoelastic materials which can substantially reduce the required critical force required for the cooling mechanism, as well as the overall refrigerant materials cost per system.

More information on the technology can be found in a recent APS Physics news article: https://physics.aps.org/articles/v13/21 and a news story from UMD: https://mse.umd.edu/news/story/the-future-of-cool-additive-manufacturing-and-niti-metal-bolster-cooling-technology

Published June 3, 2020